- | 9:00 am

Can green construction in the Middle East be a viable attempt to save the planet?

Beyond vehicular pollution and industrial emissions, the construction sector has been causing significant damage to the environment.

When you think of bustling cities like Dubai, Abu Dhabi, Riyadh, or Doha, you imagine towering skyscrapers and malls resembling modern souqs.

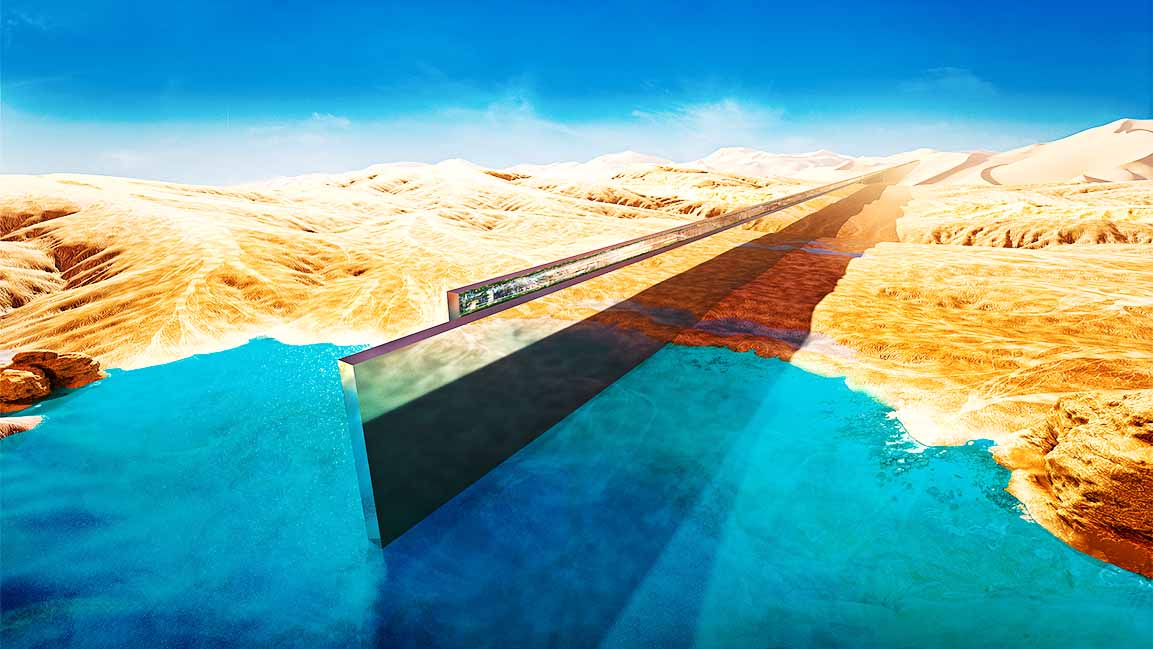

Architectural marvels including Burj Khalifa, Makkah’s Clock Tower, and Doha’s Aspire Tower define the middle eastern cityscapes. Construction sites along the way to the offices highlight the growth of Dubai’s real estate sector. Qatar is building new stadiums, hotels, and public spaces for the 2022 FIFA World Cup, and Saudi Arabia has grand plans for NEOM.

We’ve heard about the human and financial costs of the Middle East’s mega projects. But what about the environmental cost?

It may not pollute our oceans like plastic, but concrete is one of the worst pollutants. If you look at the manufacturing process, cement causes more pollution than gas-guzzling trucks by emitting carbon, dust particles, and methane.

Clusters of skyscrapers in Middle Eastern cities absorb sunlight and trap heat, making global warming worse. Yet the only solution to tackle higher temperatures caused by climate change seems to be building more closed, air-conditioned spaces.

So, what are the alternatives that reduce water consumption, use of cement, and don’t drive up costs for developers?

Green buildings, which create more renewable energy than they consume, could be a viable option, but there’s a catch. We often ignore that emissions caused by construction are higher than those from a building in its entire lifetime. The amount of energy green buildings are expected to save will take 30 to 40 years, but construction is damaging the planet.

For instance, Dubai may have the third-highest number of LEED (Leadership in Energy and Environmental Design) certified energy-efficient buildings, but is anyone looking at pollutants emitted while built?

Construction causes 40% of the world’s carbon emissions, way more than agriculture or airlines, but is hardly called out for its environmental impact. So what are the options being explored in the Middle East to adopt eco-friendly practices while assembling green buildings?

RECYCLING TO BREAK THE CYCLE OF POLLUTION

Recycling is a given to save our oceans and to deal with e-waste piling up as devices are replaced faster.

This efficient strategy is also suitable for converting industrial waste into construction material. First created in Germany, green cement is produced using fly ash, a byproduct of coal from power stations. Another granular material used in green cement is slag left behind in blast furnaces manufactured of iron.

Using fewer fossil fuels and more recycled waste in production makes green cement a low-cost construction material.

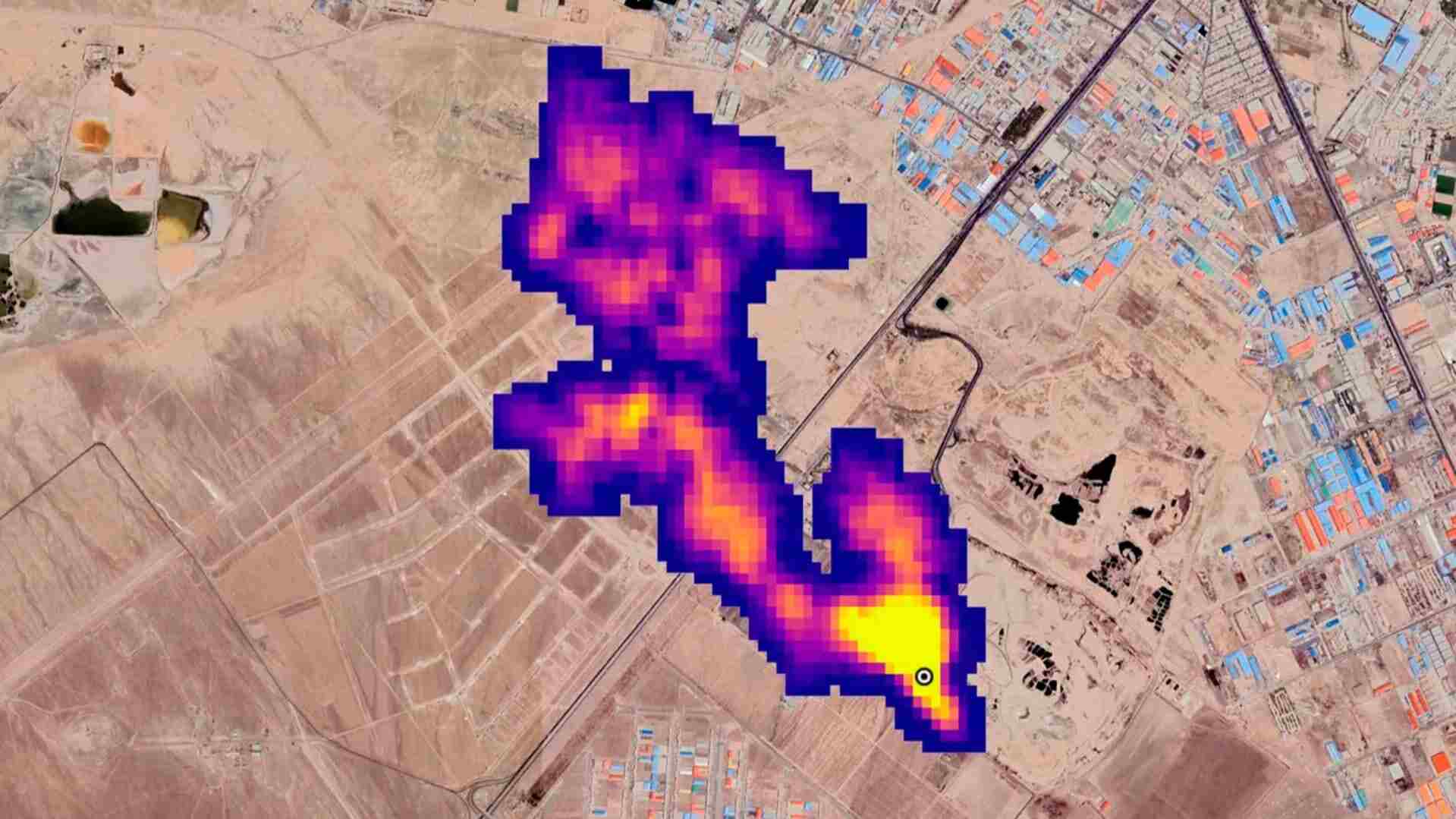

Under the new legislation, it’s also viable in a city like Dubai, where developers must use only green cement in upcoming projects. In Saudi Arabia, Aramco captures carbon from emissions to cure concrete, which hardens it faster. This rehydrates building slabs in 3 days instead of 28, saves 80% water, and reduces carbon emissions by 70%.

REINFORCING SUSTAINABLE CONSTRUCTION

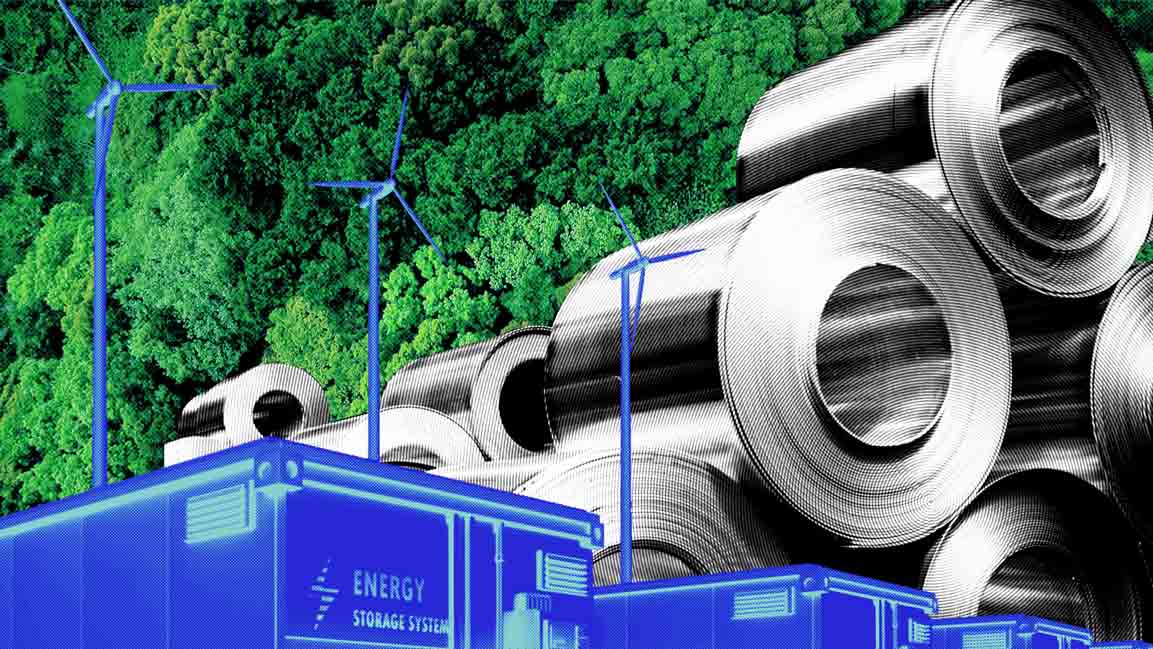

Besides concrete, steel rods are key components that hold buildings together, but emissions from their production are disintegrating the environment. The manufacturing process for a ton of steel releases two tons of carbon dioxide into our atmosphere. Damage can be reduced by replacing fossil fuels with hydrogen for producing metals. The UAE and Saudi Arabia are on track to extract green hydrogen by separating hydrogen molecules from the water via solar-powered electrolysis.

After generating hydrogen fuels, Emirates Steel and Abu Dhabi’s National Energy Company Taqa have partnered to produce green steel. Oman’s state-owned firm OQ is also planning to invest in green steel and cement production. Saudi Aramco formed global partnerships to increase polymer concrete and fiberglass bars to replace metals in construction.

As the cost of natural gas and renewable energy fall with time and coal gets more expensive, green steel is becoming a viable option to cut construction costs.

Is there anything that can’t be created using a 3D printer, from auto parts to human organs and even vegan meat? This technology is revolutionizing every industry and is even building massive villas in the Middle East. To start with, 3D printing does away with tons of construction waste. Once the design is finalized, the printer knows exactly how much material is needed. It also leads to savings by cutting down transportation costs for different components, which can print on-site.

The concrete for 3D printed homes is produced by recycling desert sand, construction waste, and ceramsite. So far, the UAE has witnessed the construction of a traditional villa in Sharjah through a 3D printer. Dubai is home to the world’s largest 3D printed building, which is 9.5 meters high, with a food area of 640 square meters.

Beyond this, 3D printed construction reduces labor costs since only three people are enough to build an entire house.

There are alternatives to making construction in the Middle East eco-friendly, but first, authorities need to identify the sector’s carbon footprint. This needs to be followed by strict legislation enforcing the use of green materials, like the one adopted in Dubai.

Developers must be aware of the long-term cost benefits of metals and cement created using renewable energy or recycled waste. Planting more trees won’t help unless emissions from concrete jungles are cut down.